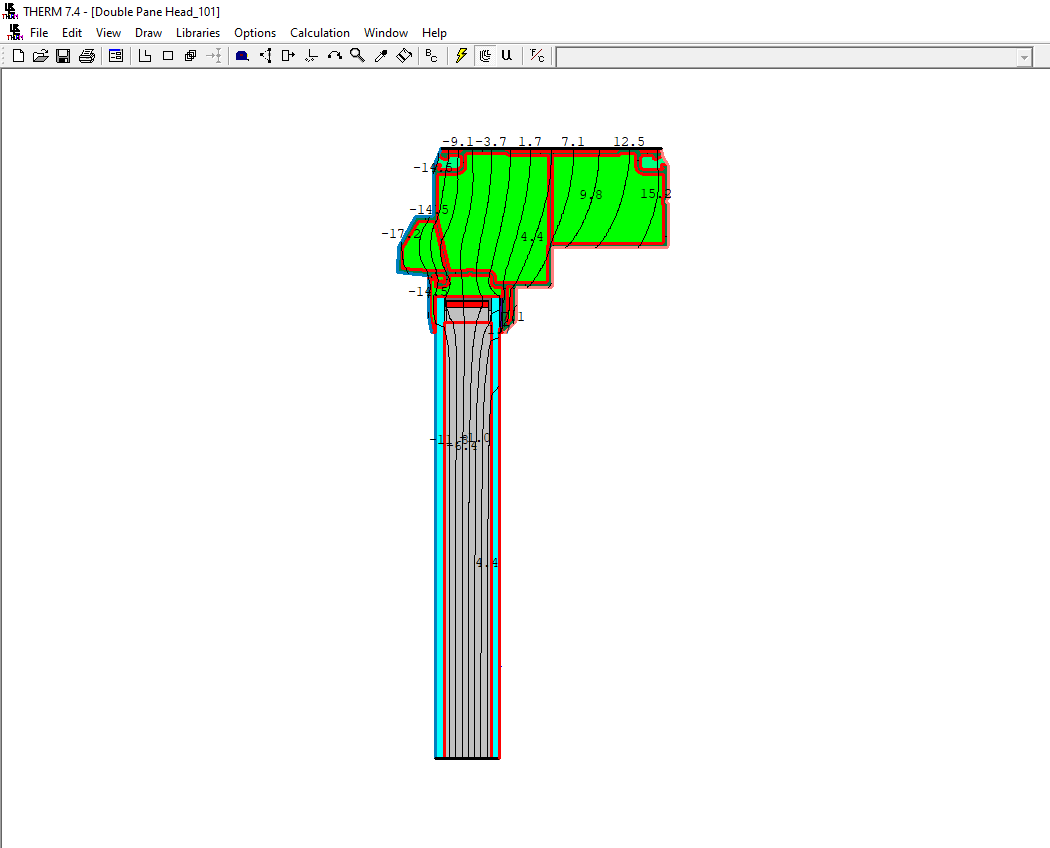

NFRC Thermal Performance Simulation

Blackwater Technical Services provides National Fenestration Rating Council (NFRC) thermal performance simulation using WINDOW/THERM to provide detailed energy demand and performance data for any window or window wall system, including:

- Overall Thermal Transmittance (U Factor)

- Overall Solar Heat Gain Coefficient (SHGC)

- Overall Visible Transmittance (VT)

- Simulated Condensation Resistance Factor (CRF)

- Simulated Condensation Resistance Values (CR)

- Dew Point Analysis

- Heat flux and Heat Transfer Analysis

- Renovation energy savings

Let us help you determine the best combination of available design features to allow you to develop a thermally efficient product.

NFRC Thermal Performance Simulation

Blackwater Technical Services provides National Fenestration Rating Council (NFRC) thermal performance simulation using WINDOW/THERM to provide detailed energy demand and performance data for any window or window wall system, including:

- Overall Thermal Transmittance (U Factor)

- Overall Solar Heat Gain Coefficient (SHGC)

- Overall Visible Transmittance (VT)

- Simulated Condensation Resistance Factor (CRF)

- Simulated Condensation Resistance Values (CR)

- Dew Point Analysis

- Heat flux and Heat Transfer Analysis

- Renovation energy savings

Let us help you determine the best combination of available design features to allow you to develop a thermally efficient product.

Consulting/Design Reviews

Blackwater staff have extensive experience in product design, construction, and engineering. We can assist project engineers, construction professionals, and product manufacturers with design reviews for constructability, ease of assembly, and technical accuracy. We can assist clients with the following:

- Research and Development support during product design

- Test plan optimization

- Test Sample Fabrication Oversight

- Construction Oversight and/or Inspections to ensure compliance with installation requirements and tested configuration

- Review of calculations, drawings, specifications, etc. for technical accuracy

- Review of field changes for impact to design and testing requirements

Consulting/Design Reviews

Blackwater staff have extensive experience in product design, construction, and engineering. We can assist project engineers, construction professionals, and product manufacturers with design reviews for constructability, ease of assembly, and technical accuracy. We can assist clients with the following:

- Research and Development support during product design

- Test plan optimization

- Test Sample Fabrication Oversight

- Construction Oversight and/or Inspections to ensure compliance with installation requirements and tested configuration

- Review of calculations, drawings, specifications, etc. for technical accuracy

- Review of field changes for impact to design and testing requirements

Forensic Engineering

Blackwater staff have extensive experience in industrial and commercial facilities design, root cause analysis, and forensic engineering. Forensic engineering and root cause analysis is a deliberate process of investigation, from product and design conception and selection, to product manufacturing, to product prototype testing, and to final installation and field testing. Water and air leaks associated with building envelope tightness from construction or product manufacturing errors can result in extensive damage with subsequent insurance losses, subrogation claims, and ultimately legal proceedings.

We will review available documentation from all aspects of the project, perform on-site inspections (including moisture testing and thermal imaging, if appropriate), interview witnesses, obtain evidence samples if necessary, perform additional testing on components or systems to mimic the installed configuration, and provide an unbiased report substantiating our professional opinion as to the cause of the issue. If necessary, Blackwater staff have experience with depositions and legal proceedings, and can support either plaintiff’s or defense cases with expert witness testimony supporting the facts of the case.

Forensic Engineering

Blackwater staff have extensive experience in industrial and commercial facilities design, root cause analysis, and forensic engineering. Forensic engineering and root cause analysis is a deliberate process of investigation, from product and design conception and selection, to product manufacturing, to product prototype testing, and to final installation and field testing. Water and air leaks associated with building envelope tightness from construction or product manufacturing errors can result in extensive damage with subsequent insurance losses, subrogation claims, and ultimately legal proceedings.

We will review available documentation from all aspects of the project, perform on-site inspections (including moisture testing and thermal imaging, if appropriate), interview witnesses, obtain evidence samples if necessary, perform additional testing on components or systems to mimic the installed configuration, and provide an unbiased report substantiating our professional opinion as to the cause of the issue. If necessary, Blackwater staff have experience with depositions and legal proceedings, and can support either plaintiff’s or defense cases with expert witness testimony supporting the facts of the case.

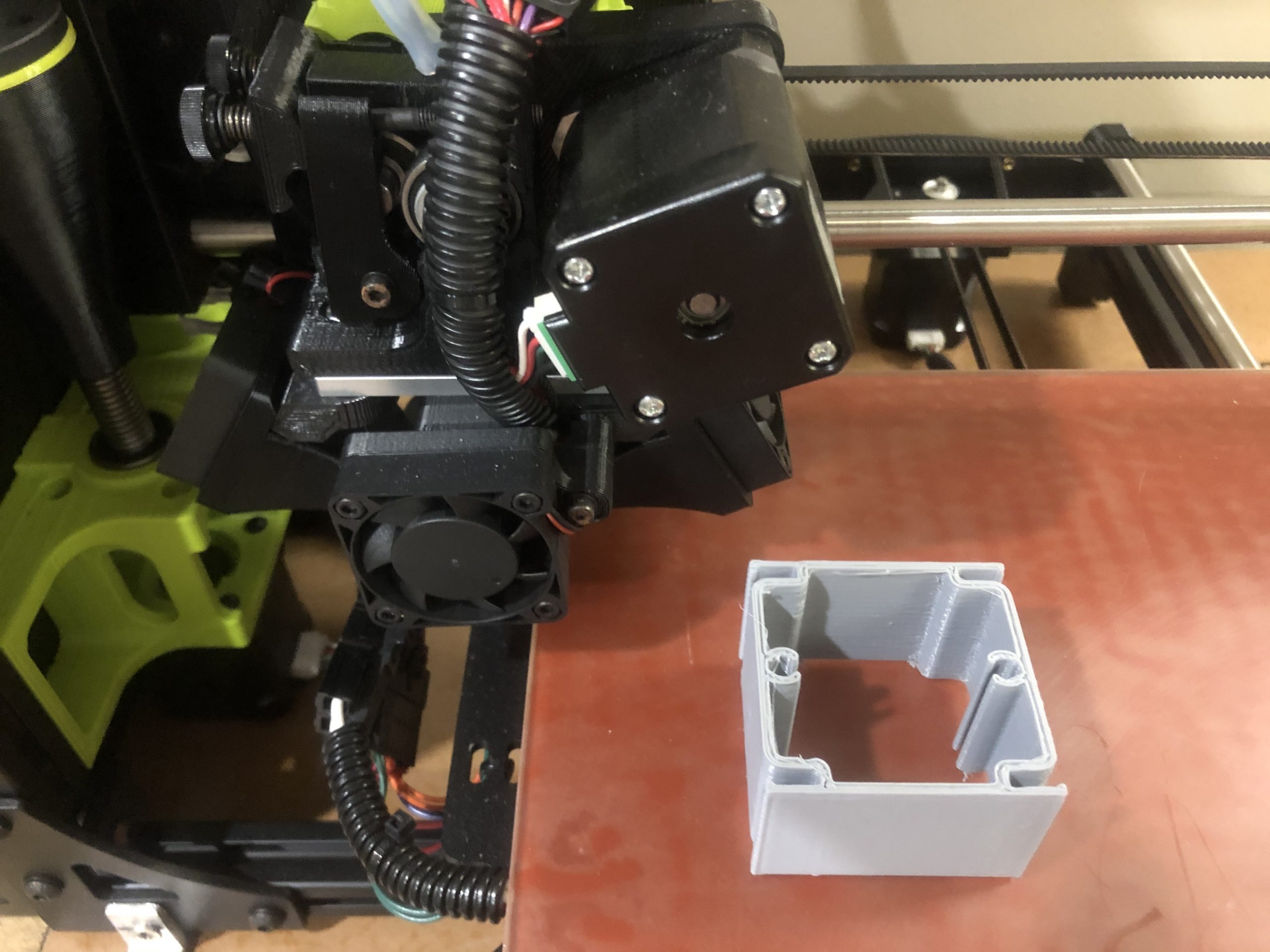

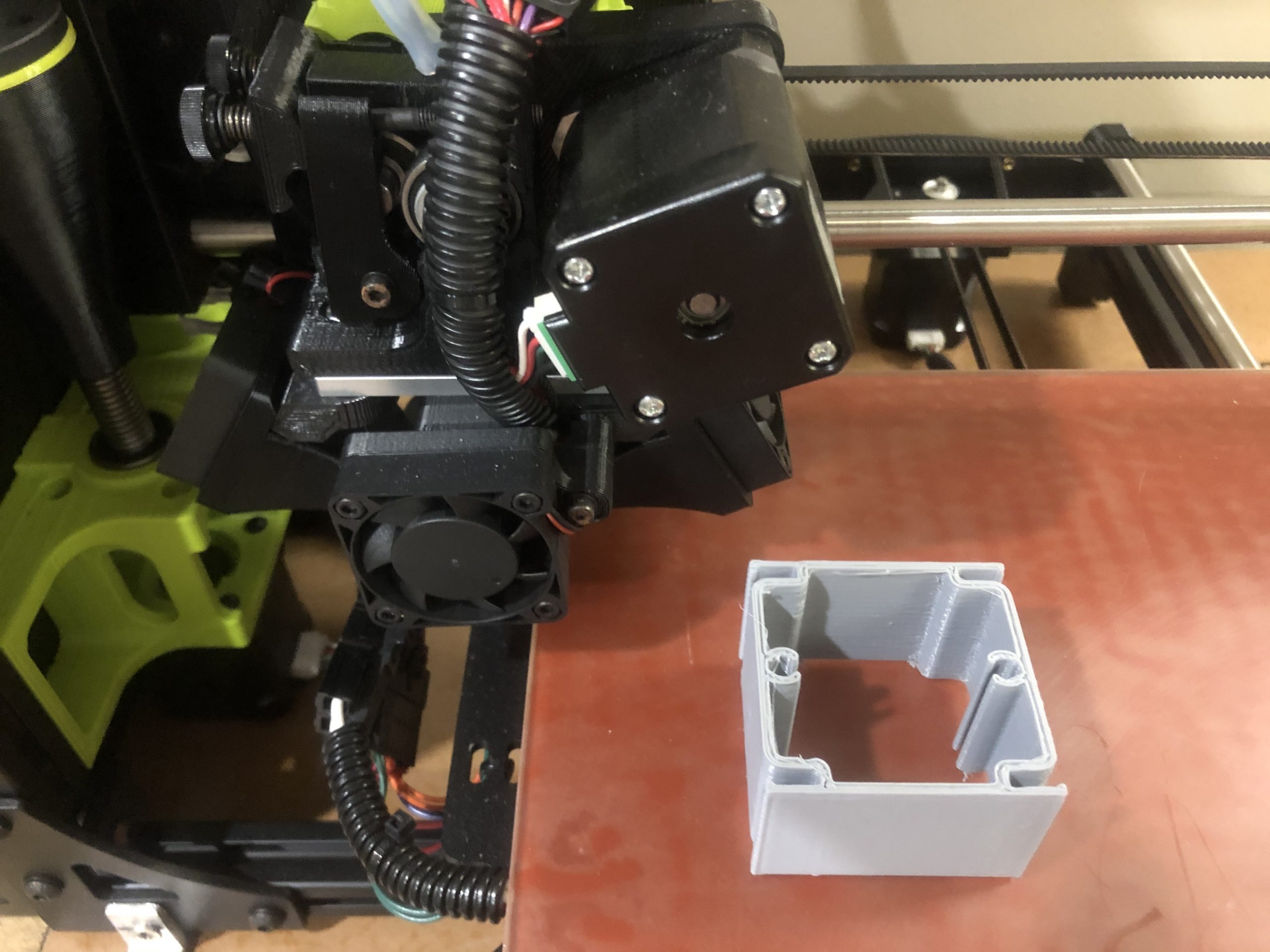

3D Printing

Blackwater can 3D print miscellaneous parts or extrusion profile prototypes for your use in product design and development. We can 3D print up to 11”x11”x9.8” in size with a layer resolution of 0.05mm-0.4mm (0.002″-0.015″) and a minimum positive feature size of 0.5 mm (0.02 in). Just send us your 3d drawing files (supported file types are .stl, .obj, .x3d, .3mf, .png, .jpg).

3D Printing

Blackwater can 3D print miscellaneous parts or extrusion profile prototypes for your use in product design and development. We can 3D print up to 11”x11”x9.8” in size with a layer resolution of 0.05mm-0.4mm (0.002″-0.015″) and a minimum positive feature size of 0.5 mm (0.02 in). Just send us your 3d drawing files (supported file types are .stl, .obj, .x3d, .3mf, .png, .jpg).

Research and Development

Blackwater Technical Services provides essential research and development services to our clients as necessary. Need to assess stiffness or deflections on a new extrusion profile or a determine a new anchor capacity? Looking for a maximum design pressure? Trying to determine the best methods of reinforcement or an appropriate glass interlayer? Need to assess glass bite for a glazing system? Before you go to the expense of fabricating multiple samples, let us perform limited R&D testing and/or design reviews to help you determine if you’re ready for market! From full service assembly and testing by our technicians to do-it yourself assembly in one of our test chambers (tested by our techs), we can help. We can also design, fabricate, and install test equipment in your facility should you want to do extensive in-house R&D!